Customer Services

Copyright © 2025 Desertcart Holdings Limited

🖨️ Flex your 3D printing game with magnetic precision and zero hassle!

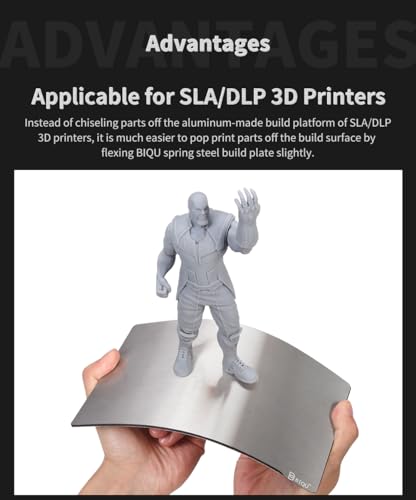

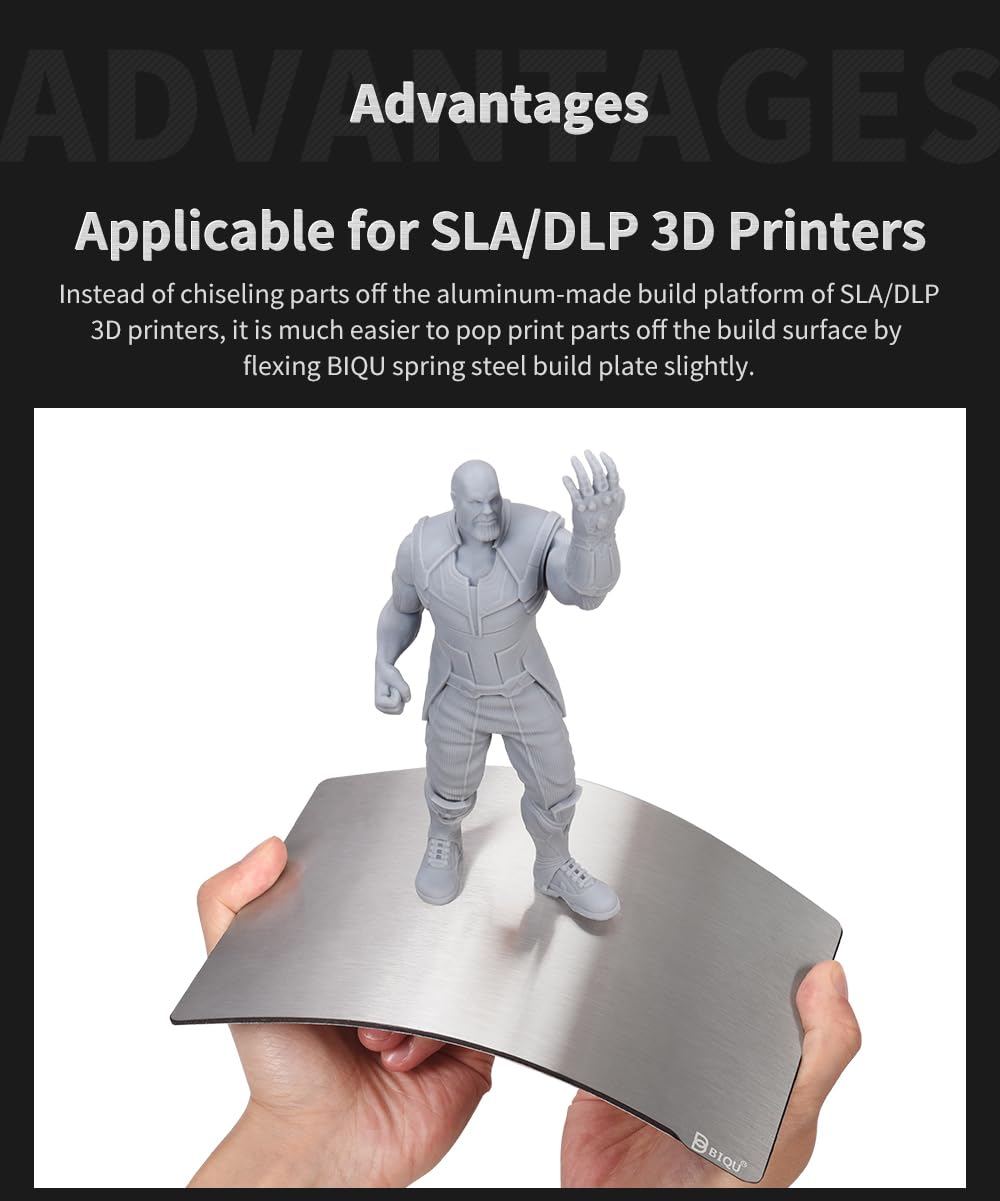

The BIQU 2PCS Magnetic Flexible Steel Plate is a 150x95mm resin build platform designed for Elegoo Mars 3/Mars 3 Pro SLA LCD resin 3D printers. Made from durable US-imported spring steel with a special wire-drawn surface for superior adhesion, it features a strong magnetic backing for secure placement and an ergonomic handle for easy removal. This flexible plate eliminates the need for scrapers, protecting your prints and build surface while streamlining post-print cleanup.

| ASIN | B0CHDRYBQP |

| Best Sellers Rank | #97,161 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #2,080 in 3D Printer Accessories |

| Date First Available | September 5, 2023 |

| Item Weight | 7.2 ounces |

| Manufacturer | BIGTREETECH |

| Package Dimensions | 5.91 x 3.74 x 0.12 inches |

J**.

Photon Anycubic X you might want to...

...scuff up the surface a bit more. My experience was I got the little envelope from amazon and opened it up slapped it on the build plate - calibrated... and did a few test prints. It was a bulky item I kept trying... so the plate just kept coming up empty. I was immediately frustrated... but also realized this print item fell off the original build pate too! (also am using ptfe lube on the new fep) So I did the nasty and grabbed some sandpaper and took a few angry swipes at the Biqu metal plate. Just quick swipes to get a bit more Texture. And BOOM This thing works AMAZINGLY on Everything! The days of using a dam razor or chisel are over! No need for a bulky raft! Just slice that thing right on the build plate!! You can pop it off with ease and have no damage to the part and waste less resin. Final note: If you are worried about damaging the new biqu magnet plate you just bought by scuffing it up a bit more as I mentioned above you can flip the metal sheet over and have the original manufacturing texture that came with the metal plate. and that at its default texture works just fine for small parts like minis. This thing is such a simple and great idea. Should be a default on ALL resin printers. Amazing product.

R**K

Item is as Described and Works as Intended with the proper prep work!

I bought this product, slightly skeptical as I know magnetic force can be somewhat touchy depending on surface area and adhesion can vary based on surface preparation and the quality of product used. This product came in with 3M, chemical-resistant tape and has more than enough surface area to hold the steel plate to the build plate without any issue. Reviewers who have had the plate fall into the vat or come off in any way must have done something wrong as I cannot see any straight-pull force breaking the plate free from the magnet as I sometime struggle to remove it even when I am trying to and from a corner. The Saturn's bed has a blasted finish so the surface is less than ideal for adhesion, but so long as users follow the instruction below I cannot foresee any future issues. Clean the entire build plate and head with iso. alcohol or acetone to remove any resin residue. If your build plate has any SUBSTANTIAL marks from removing prints, no matter if they are gouges or raised material, those have to be removed so break out some 600g paper, lay it flat on a hard surface, and lap your build plate back to flatness. CLEAN AGAIN with iso. or acetone if you lapped anything to remove both the grit, bed material, any anything that could have been on the paper. Heat the build plate and the magnetic sheet with a blow dryer or some other heat source for 5 to 10 mins. so that it is WARM to the touch through and through (not just for a few seconds and then cools back down). Install your build plate on the machine, upside down and tighten it well. Remove the backing paper on the magnetic sheet from just one end of the sheet, keeping it on the rest so you do not physically touch the adhesive. Lightly start the short edge on the plate and, when you t it where you want it press it down, starting from the middle and working outward. Allow the rest of the magnetic sheet to contact the build plate, removing the backer as you go, and pressing down from the middle out to release any air that may become trapped. When the entire mag sheet is laid out, take a microfiber and press/rub all over it for several minutes as both the sheet and the build plate cool. Most adhesive have a set-up period, so waiting to print for a day would be ideal, but even a few hours would be good to allow things to set-up. I began printing entire plates immediately after install and have no issues. I have also tried to work a corner of the magnetic sheet up (just to see if it would give up easily) and could not do so. This system makes printing easier and better. You may still have to scrape the prints off, but at least you are not scaping your build-plate material and removing the plate allows you to keep the head attached to the machine, saving resin, alcohol life, and reducing cleaning time. Addition considerations: The surface of this plate is rather smooth to allow prints to break free. Before I used mine I blasted it with 120g media. The blasting process creates a surface much like your stock build plate and insures that prints will stick every time without fail, but doing so makes it so you will not be able to easily break your parts off the plate. Blasting CAN warp the plate so if you do it, go slow and do both sides evenly so you do not induce too much heat. I did not try the product with the stock surface so cannot attest to print adhesion.

C**N

Works out the box

This thing has been AMAZING for protecting my new resin printer and its bed, and with how easy the Mono X is to level, this was a peice of cake! The on thing to be aware of is that if you arent careful, this can rip your glove, which happened to me a few times. Few things to note: Big Print? Hard to flex, so you might need to scrape it off, but this is better to replace than the entire build plate. Magnetic force is STRONG, recommend laying both on sides, at 45 degree angle, and then gently nuding them together, with your hands outta the way so you dont get pinched. Past that, I ADORE how easy it has been to use and has made my experience as a new resin printer hobbyist MUCH better!

S**B

Dang! It werks!!

Cheaper than the leading brand I was skeptical it would do the same job as that leading brand. No instructions, but then again it's not rocket surgery to work it out. After cleaning the build plate with acetone and scotchbrite, I found the only major issue with this product. The 3M? adhesive pad does not adhere! It feels like it should, but when removing the flex plate you end up removing the whole thing! I can only imagine it being worse for those who skimped on cleaning the build plate. However not being one to give up on a good idea I applied a copious amount of thin cyanoacrylate to the build plate, applied the 3M adhesive pad to the plate and hit it with accelerator. Now we have a nice tenacious bond the flex plate comes off without it's mating surface. After rehoming the now thicker build plate I did a 4 hour print on the Mars 3. No issues with first layer or subsequent ones on the flex plate. Easy to remove thanks to the little sticky outy tab, and over to wash station. Flexi flexi and off popped the print into the cleaning tank. Very nice!! Just needs a better adhesive solution. But recommended all the same!

G**E

Es del tamaño perfecto y facil de instalar, solo hay que clarificar que se necesita observar el tamaño de la placa de construccion, no el area de impresion, sin embargo ese fue error mio, al creer que son el mismo concepto.

Trustpilot

2 weeks ago

3 weeks ago